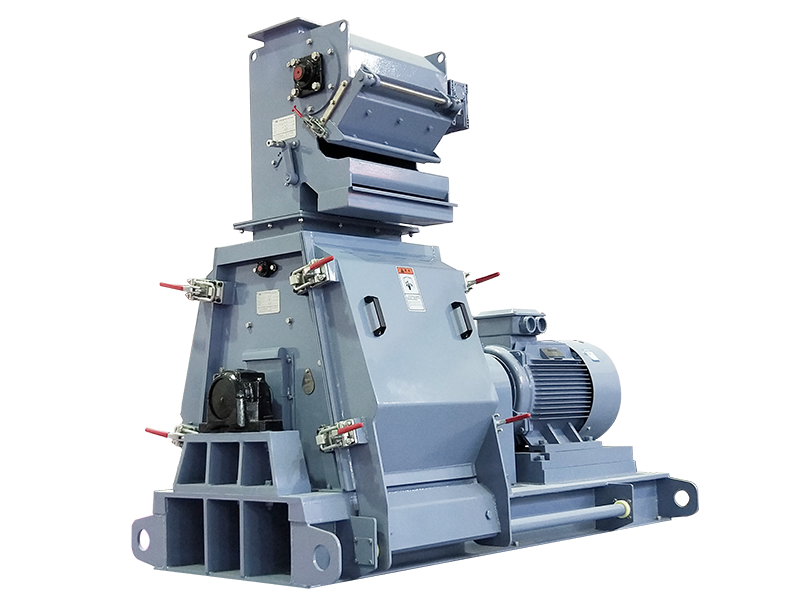

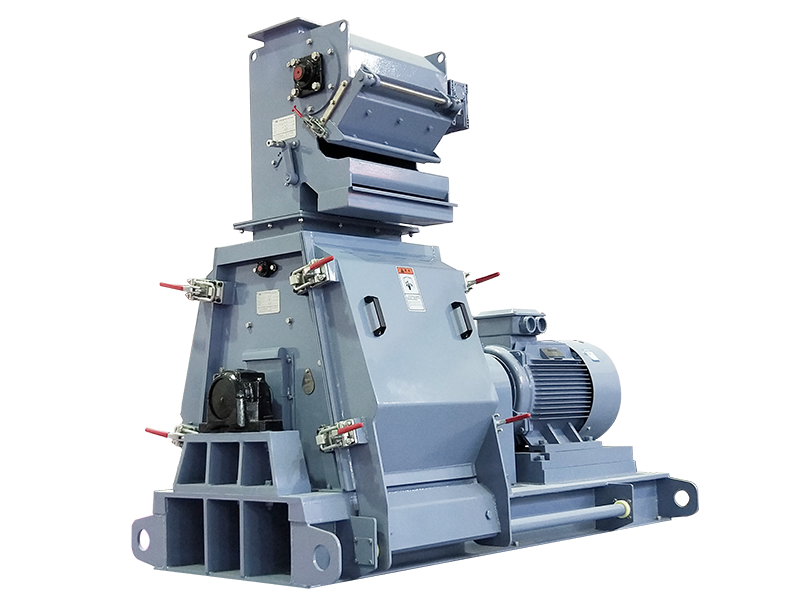

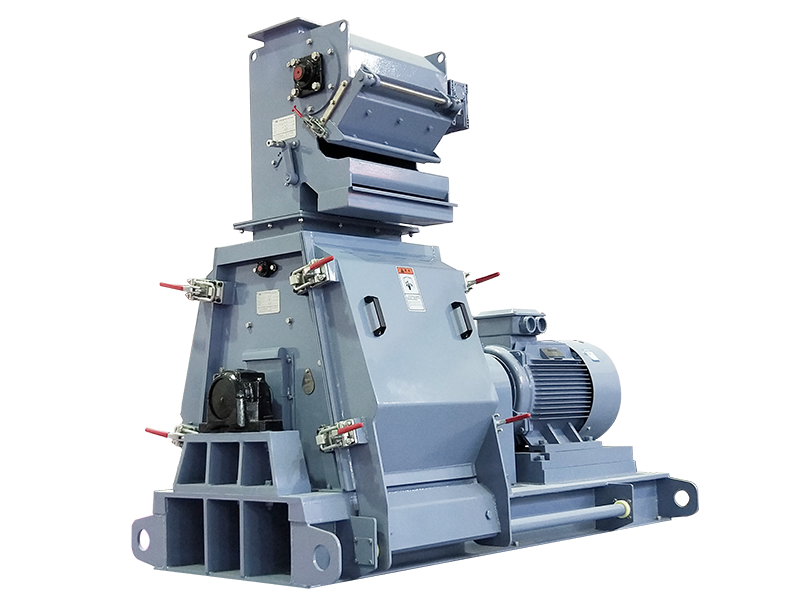

Curshing Machine-The hammer mill is an important equipment for the raw material grinding process. The hammer mill can grind the raw materials ingredients into the required size. It is suitable for small or medium sized feedstuff pellet mill plant. While if you manage a large scale feedstuff pelletizing factory, the water drop hammer mill is an ideal choice.

Mixing Machine-Mixing is one of necessary processing in animal feed pellet line. Proper mixing will lead to increase diet uniformity and improve the feedstuff quality. We will provide two kinds of high efficiency feed mixers: twin shaft mixer for particle materials and screw belt mixer for powdered materials. Both of them are equipped with atomizing spraying system to add needed liquids which can improve feed pellets quality.

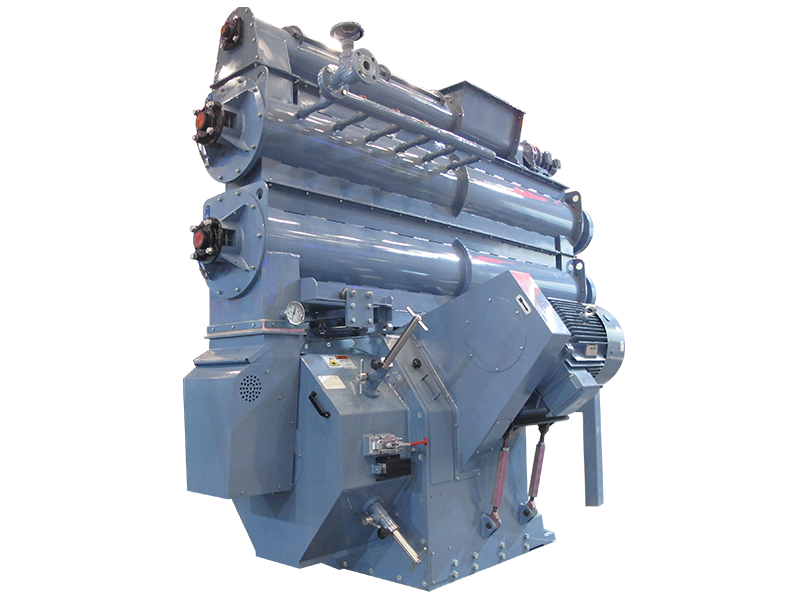

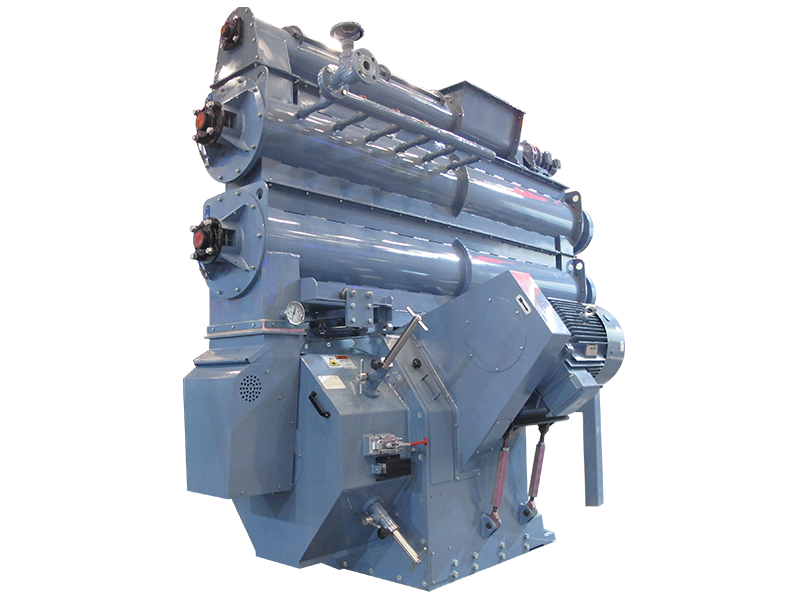

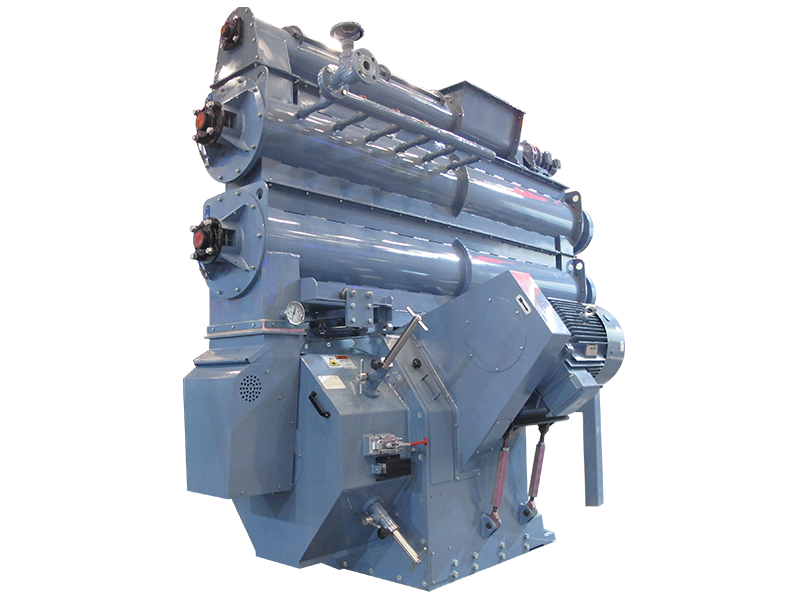

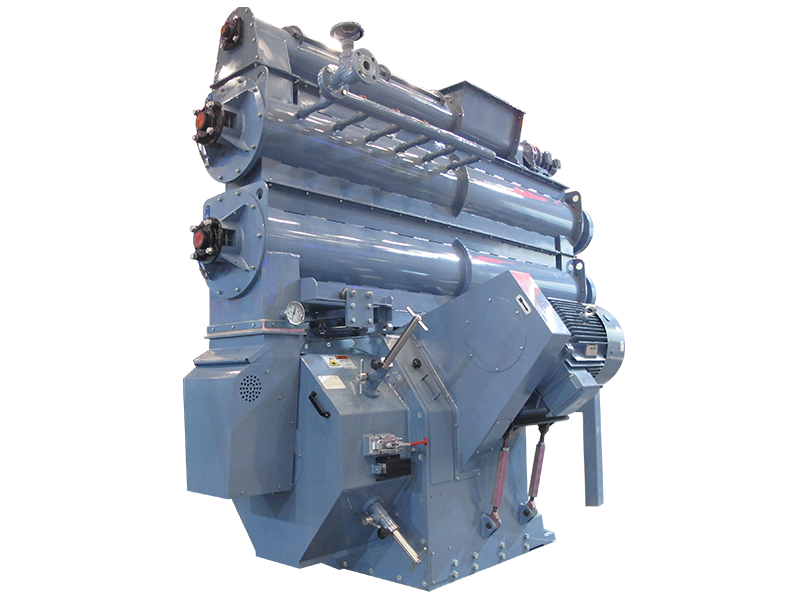

Pelletizing Machine-Feed pelletizing machine is the key feed equipment for the animal feed pellet line. The feed pelletizing machine is the ring die design which is broadly used to large capacity feed pellets production. If you have another questions about feed pellets production requirements like capacity or scale, please send e-mail to us for more support and guidance.

Cooler-Getting out of the feed pelletizing machine, the feed pellets with high temperature and large moist need cooling by counterflow cooler. The these feed pellets can be crushed, screened or packed. Through the cooler, the feed pellets are decreased the temperature and moisture for next processing.

Crumbler-Because different animal such as poultry, cattle and pig feed pellets are with different sizes. Some big feed pellets should be crushed into small particles. The feed pellet crumbler is the right equipment for the feed pellets crushing.

Rotary grading sieve is used to screen and grade the feed pellets. After this processing, you can get qualified feedstuff pellets without powder

Packing-In order to pack for storing, transporting and selling, automatic packing machine can weigh and pack the feedstuff pellets automatically with high accuracy.

makes 2-8 mm diameter animal feed pellets. Such as 2-4mm diameter chick feed pellets and pig feed pellets.2-5mm rabbit feed pellet, 4-8mm cattle or sheep feed pellets. The last pellet length can be adjusted.

After installation and adjust,we will training our customer's work how to operate;

Training worker how to maintain and protect.

According features,we will make a complete maintain rules for you, contains how to maintain,when to maintain,who maintain

Our company after-sale department will call you at regular intervals,ask if maintain and give advice.